Odoo Manufacturing

Manufacturing is a complex and dynamic process that involves many factors, such as demand, supply, resources, quality, and costs. To manage and optimize the manufacturing process, you need a powerful and flexible software system that can help you plan, execute, and monitor your production activities.

Odoo is a software system that offers a comprehensive suite of applications for manufacturing planning. Odoo allows you to create and manage your products, bills of materials, ranges, work centers, work orders and production orders. You can also use Odoo to forecast your demand, replenish your inventory, plan your production, track your progress, and analyze your performance.

In this blog post, we will explore some of the key features and benefits of Odoo manufacturing planning. We will also show you how to use Odoo to plan your production process simply and efficiently.

Key Features and Benefits of Odoo Manufacturing

Odoo Manufacturing has many features and benefits that can help you improve your manufacturing efficiency and profitability. Here are some of the main ones :

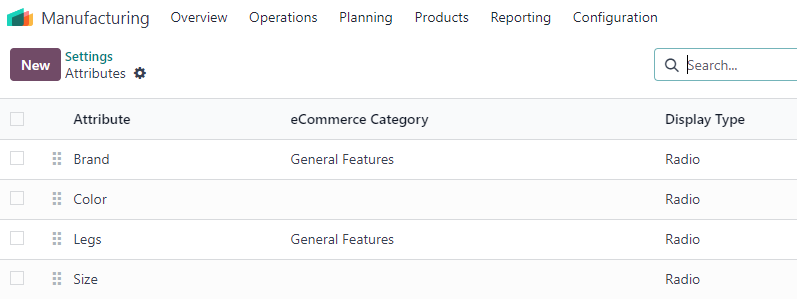

• Product Configuration: You can configure your products with various attributes, such as variants, categories, prices, and descriptions. You can also configure the manufacturing lead time, production order preparation days, and routing for each product. These settings will affect how Odoo calculates the availability and delivery date of your products.

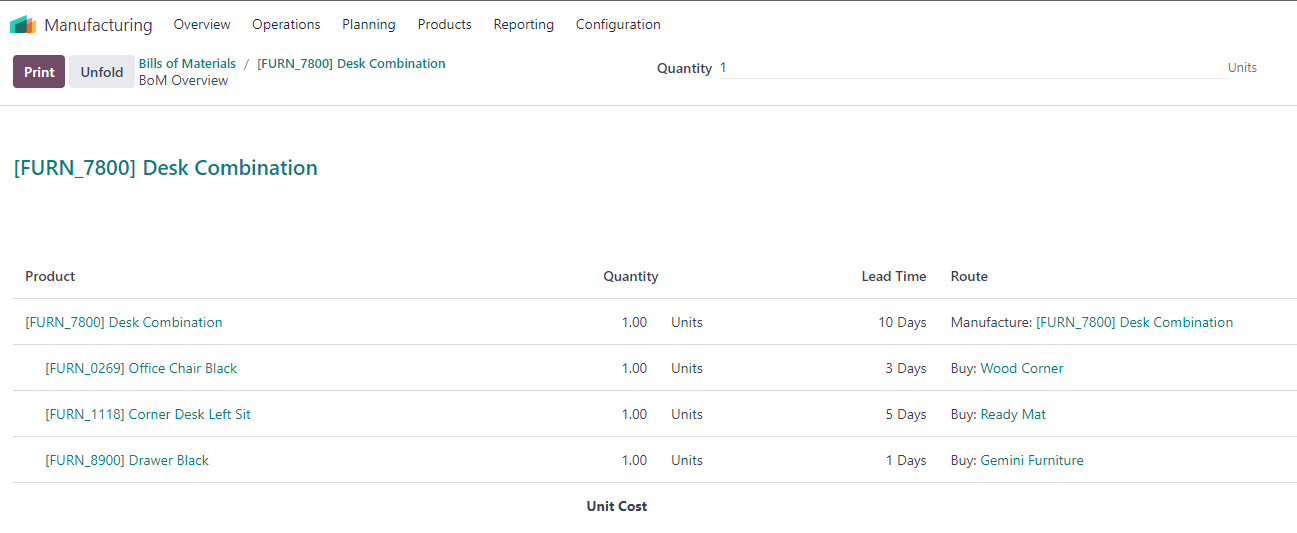

• Bill of Materials : You can create and manage your bill of materials (BOM), which are the lists of components and quantities necessary to manufacture a product. You can also use the BOM preview to see the availability and delivery times of your product and its components. You can also check your product cost and margin based on component cost.

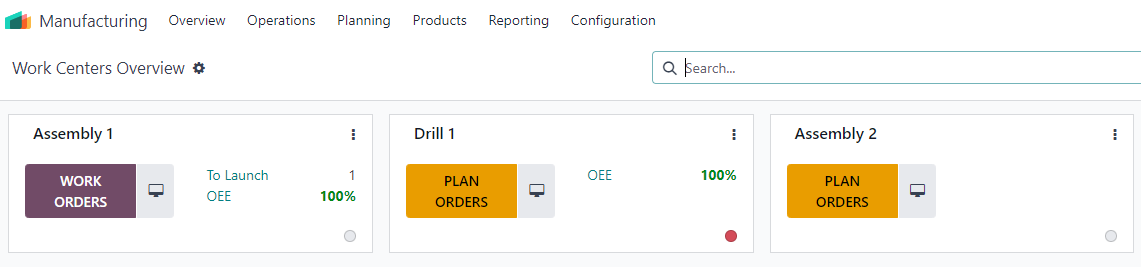

• Routings and work centers management : You can define and manage your routings, which are the sequences of operations and work centers necessary to produce a product. You can also define and manage your work centers, which are groups of machines or resources that perform similar tasks. You can assign capacities, costs, and efficiencies to your work centers, and track their utilization and performance.

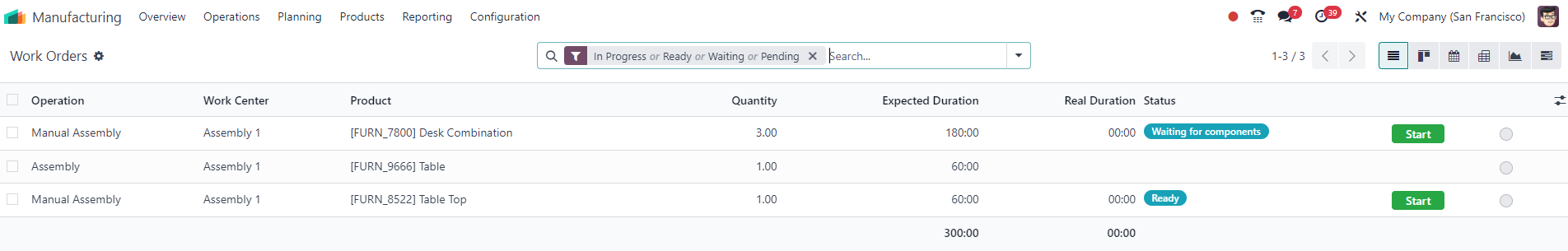

• Work orders and production orders management : You can create and manage your work orders and production orders, which are the documents that specify the details and instructions for manufacturing a product. You can also use the barcode scanner to scan work orders and production orders, and update production status and quantity. You can also print labels and reports for work orders and production orders.

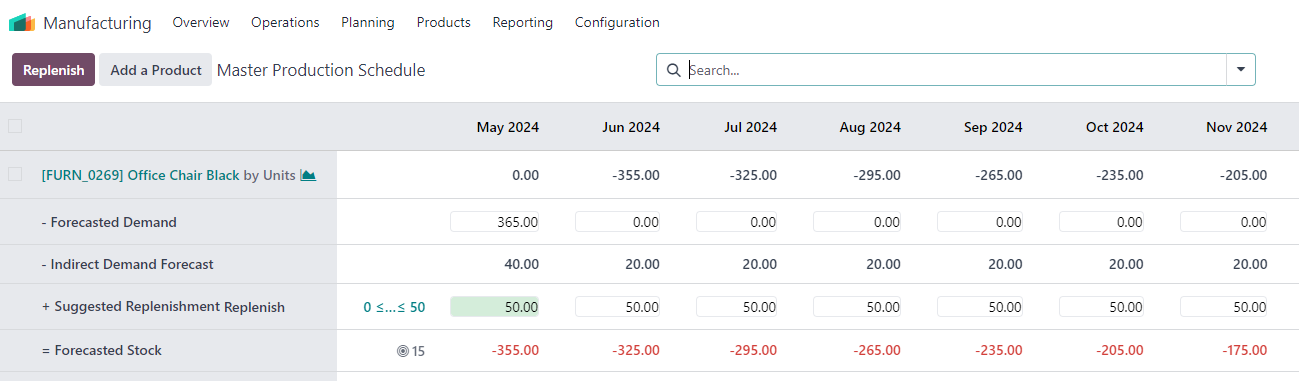

• Replenishment and forecasting : You can use replenishment rules to trigger replenishment of your products and components based on actual demand. You can also use the master production schedule to replenish your products based on forecasted demand and actual demand. You can also use the purchasing module to replenish outsourced products or purchased components.

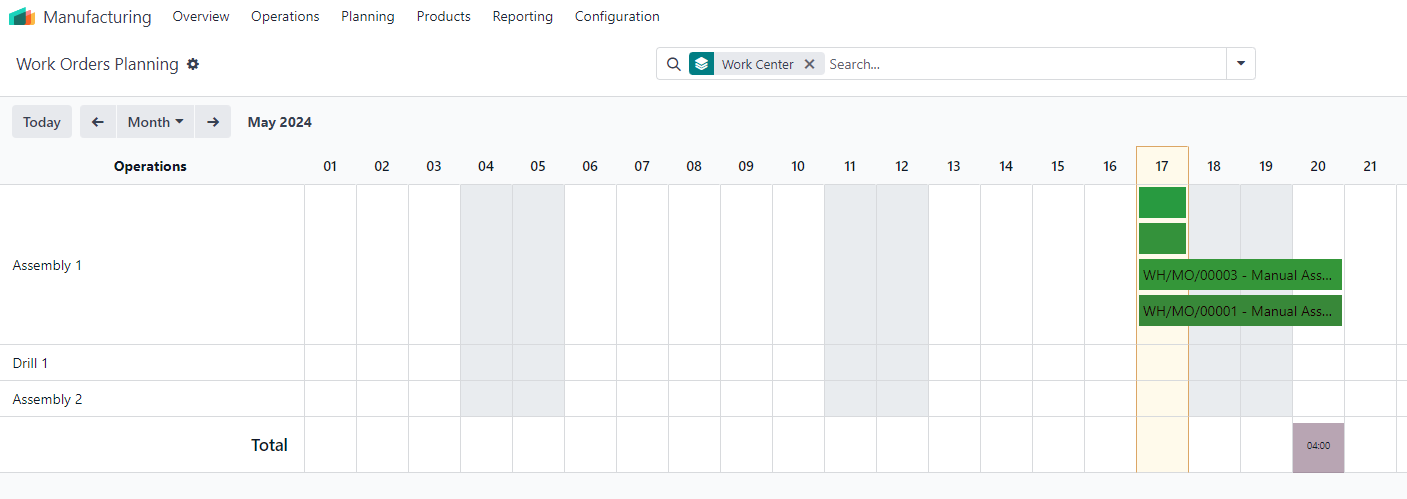

• Planning and Scheduling : You can use the planning module to plan and schedule your production process per workstation. You can view planned work orders on the calendar, edit and optimize them using drag and drop. You can also use color matching to identify production orders that belong to the same product. You can also use the Gantt view to see dependencies and conflicts between work orders.

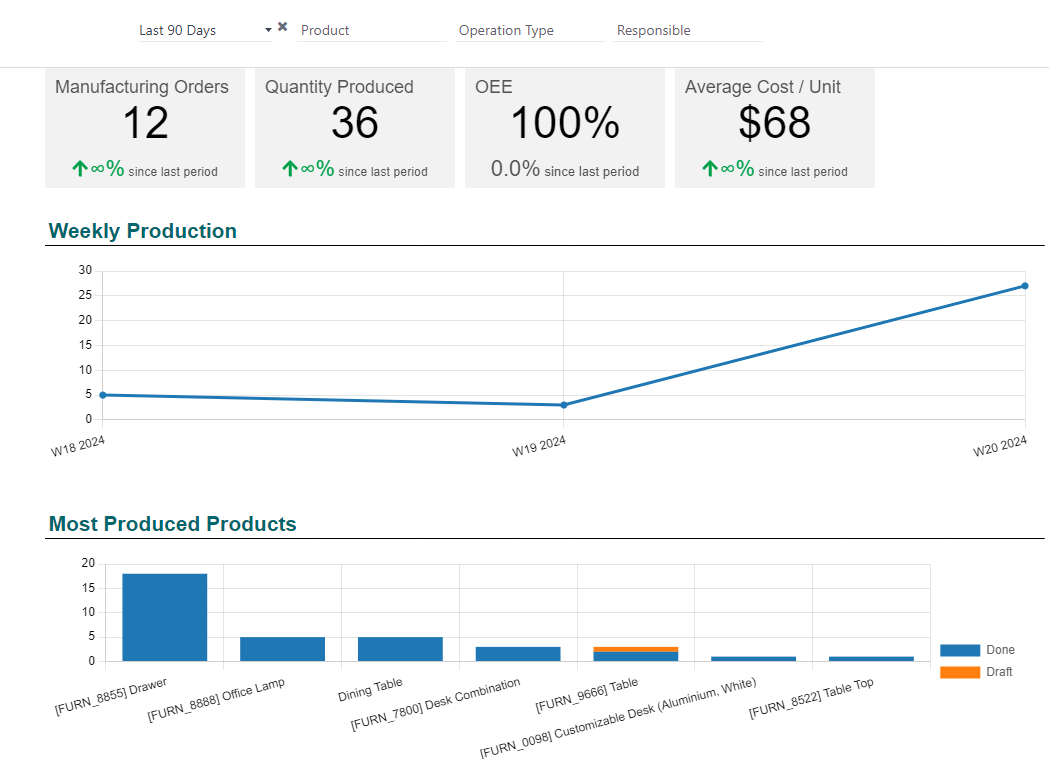

• Monitoring and reporting : You can use the dashboard to track the progress and status of your production activities. You can see the number of products to be produced, the number of products produced, the number of products in progress, and the number of products overdue. You can also use the reports to analyze the performance and efficiency of your production process. You can see cost distribution, quantity variance, quality issues and work center productivity.

How to use Odoo manufacturing ?

To use Odoo manufacturing planning, you need to follow these steps:

• Step 1: Configure your products, routes and replenishment rules. You need to configure the manufacturing lead time, days to prepare the manufacturing order, and the route for each product. You also need to configure replenishment rules to trigger replenishment based on actual demand.

• Step 2 : Create and manage your schedules, routes and work centers. You must create and manage your bills of materials, which are the lists of components and quantities needed to produce a product. You also need to create and manage your routes, which are the sequences of operations and work centers needed to produce a product. You also need to create and manage your work centers, which are the groups of machines or resources that perform similar tasks.

• Step 3 : Estimate the delivery date and availability of your products and components. You must use the sales order forecast report to see the expected availability date of the product. You should also use the material invoice overview to see the estimated availability dates of the components. You also need to use the days to prepare the production order to create the production order in advance.

• Step 4 : Restock your products and components. You should use the master production schedule to replenish your products based on forecasted demand and actual demand. You should also use the replenishment report to replenish your components based on replenishment rules. You should also use the purchasing module to replenish outsourced products or purchased components.

• Step 5 : Plan and schedule your production process by work center. You need to use the planning module to plan and schedule your production process by work center. You need to see planned work orders on the calendar and edit and optimize them using drag and drop. You should also use color matching to identify manufacturing orders that belong to the same product. You should also use the Gantt view to see dependencies and conflicts between work orders.

• Step 6 : Track and report your production activities. You should use the dashboard to track the progress and status of your production activities. You need to see the number of products to be produced, the number of products produced, the number of products in progress, and the number of products behind schedule. You should also use the reports to analyze the performance and efficiency of your production process. You need to see cost breakdown, quantity variance, quality issues and work center productivity.

Conclusion

Odoo is a software system that offers a comprehensive suite of applications for manufacturing planning. Odoo allows you to create and manage your products, your bills of material, your routes, your work centers, your work orders and your production orders. You can also use Odoo to forecast your demand, replenish your inventory, plan your production, track your progress, and analyze your performance.

Odoo manufacturing planning can help you improve your manufacturing efficiency and profitability by optimizing your production process and reducing your lead times. Odoo manufacturing planning can also help you improve customer satisfaction and loyalty by improving the accuracy and reliability of your delivery date estimate.

If you want to know more about Odoo manufacturing planning, you can visit the Odoo official website or contact us for a free consultation. We can help you implement and customize Odoo for your specific needs and preferences. We can also provide you with training and support to help you get the most out of Odoo.